Picture this. You’ve poured your heart into designing a sharp board game. Bright artwork. Clever mechanics. The whole shebang. But when players crack open the box for the first time, it crumples like a flimsy fast-food wrapper. Oof. That first impression? Shot. On the other hand, you’ve spotted those high-end games. The packaging feels like a little event. All solid and satisfying. But the price tag hits your indie budget hard. Sound familiar? If you’re deep in game development, you know the drill. Wrestling with cost vs. durability in custom paper boxes is just part of the gig. It’s not only about slapping your logo on a cardboard sleeve. It’s about picking something that guards your components. It wows your backers. And it doesn’t wipe you out before launch.

In this post, we’ll break it down nice and easy. Step by step. How to handle the trade-offs. Spot what counts for your game’s budget. And land on packaging that packs a punch. We’ll pull from real-life spots in the gaming world. Throw in some solid numbers from shop talk. And keep it straight. No extra junk. Just stuff you can use right away. To help you pick the right custom paper box. Without kicking yourself at 2 a.m.

The Tug-of-War: Why Cost and Durability Matter More Than You Think

Let’s get straight to it. In the indie game world, every buck matters. You’re likely scraping by on Kickstarter cash. Or piecing together a small print run. Packaging often draws the short straw. But here’s the thing. Skimping on your custom paper box isn’t just sloppy. It’s a gamble. A weak box means bent cards. Chipped tokens. And returns that chew up your profits. I’ve chatted with devs who’ve had to redo whole batches. All because the mail carrier folded their game into a mess.

Durability? That’s your quiet closer. It keeps everything safe through shipping battles and shelf time. It turns a one-off buyer into a loyal fan. Cost is the bouncer, though. You want something cheap up front. But it shouldn’t bite you later with gripes or waste. Balancing cost vs. durability comes down to grasping your game’s path. How it’ll move from your warehouse to tables around the globe.

Think about a medium card game run. Say 1,000 units. A plain box might cost $0.50 a pop. But if 10% show up banged up, that’s $50 in refunds. Plus the hassle. Step up to a tougher one at $0.80? No returns. And players buzz about the “solid feel.” That’s the kind of math that nags at you in the dark.

You know, I once heard from a guy at a con. He said his first game shipped fine locally. But cross-country? Disaster. Boxes split open. Components everywhere. He learned quick. Durability isn’t a nice-to-have. It’s gotta match your reach.

What Counts as “Durable” in a Custom Paper Box?

Durability isn’t some fuzzy term. It’s real toughness you can measure. For game boxes, that means crush resistance. Edge guards. And how it stands up to moisture or rough knocks. Paper boxes win here. They’re light. Yet you can tweak them just right. Kick off with 300gsm cardboard for daily strength. Or add rigid board for that tank setup.

From factory floors I’ve peeked into, they run key checks. Drop tests from three feet onto concrete. Stack pressure—how many it can hold without folding. A decent custom paper box shrugs it off. And don’t overlook the glue. Water-based stuff sticks better in wet spots than hot melts. Those can turn yellow after a while. Tiny thing. But it spares you grief during steamy con weeks.

That said, durability ties into your game’s vibe too. A quick-play card set doesn’t need fortress walls. But a hefty eurogame with wooden bits? Yeah, beef it up. I’ve seen boxes that lasted through kids’ hands at family nights. Others that gave up after one road trip. Pick wrong, and you’re mailing apologies.

The Sneaky Downsides of Going Too Cheap

Ever grabbed “budget” boxes off the web? And watched them land flat as old pancakes? Yeah, been there in stories. Low-price picks often shave on thickness or finishes. Leading to scratches. Rips. Or that stale whiff after half a year stored away. Packaging folks’ data shows these cheap ones flop 20-30% more in travel than middle-ground ones. For games, that’s your heart exposed. For real.

But hold up. It’s not all bad news. You can stretch cheap without full flop. Pick matte lamination instead of shiny. It gives better hold and wear fight for a few cents extra. Just keep in mind. The true hit from cheap is the chance you miss. When players bail on your game for one that seems made to stick around.

And hey, sometimes it’s funny how it plays out. A buddy of mine tested a bargain box by leaving it in his truck for a week. Rain hit. Box turned to mush. Lesson? Test in the wild, not just on paper.

Key Factors to Weigh When Picking Your Custom Paper Box

Okay, enough chat. Let’s dig into the meat. Choosing the right custom paper box for your game’s budget means eyeing materials. Tweaks. And how it meshes with your setup. We’re talking everyday choices that fit how to choose the right custom paper box. Without making it a headache.

Material Breakdown: From Basic to Bulletproof

Materials kick off the cost vs. durability face-off. Paper boxes rule for games. Recyclable. Easy to print. And they scale well. But cardboards vary big time. Here’s a simple run-through.

- Standard Cardboard (200-300gsm): Your starter choice. Light. Inexpensive ($0.30-$0.60 per unit for 1,000 run). Fine for nearby shipping. But pile them up? They squash easy. Perfect for test runs or digital extras.

- Rigid Paperboard (350-500gsm): The go-to for most small crews. Gives real spine without jacking prices ($0.70-$1.20). Tackles shipping like a pro. Say, shielding a 100-card deck on a bumpy UPS trip. Green perk: Often from reused pulp.

- Kraft or Corrugated Layers: For big leaguers like board games with thick pieces. Kicks in at $1.00. But it shrugs off twists. Catch? It’s bulkier. So watch for shipping bumps.

Quick tip. Blend them. Rigid shell outside. Lighter stuff inside for separators. Cuts weight by 15%. While keeping strength up.

| Material Type | Avg. Cost per Unit (1K Run) | Durability Rating (1-10) | Best For |

| Standard Cardboard | $0.30-$0.60 | 5 | Light card games, prototypes |

| Rigid Paperboard | $0.70-$1.20 | 8 | Full board games, retail shelves |

| Corrugated Kraft | $1.00-$1.50 | 9 | Heavy components, international shipping |

This chart comes from talks with printers who’ve packed up Catan knockoffs to lone-wolf tales. Adjust for your order size. Smaller lots hike the per-piece tab.

One more thing on materials. I’ve run into cases where folks mix in a touch of foil for flair. But it can soften edges if not done right. Always ask for swatches. Feels old-school, but it works.

Customization That Pays Off (Without Breaking the Bank)

Who says tough can’t be cool? Customization lets you weave your game’s spirit in. Like pressed icons or foil titles that shine under lights. But budgets get testy here. Every bell adds to the bill.

Keep it basic at first. Full-color print on the outside for that grab-you unbox. Toss in spot UV for feel on big spots. Like your logo. It’s an extra $0.10. But it hits like fancy. For strength, try fold flaps or magnet shuts. They lock contents tighter than plain folds. Halves damage in what I’ve seen.

On batch sizes. Tiny runs under 500? They bump costs 50%. So think ahead. And sure, you might nix that crazy cut shape sometimes. It’s neat. But it thins edges unless backed up. I recall one dev who went curve-happy. Box ripped mid-con demo. Ouch. Takeaway? Function first. Style second.

Customization can sneak in fun too. Imagine a box that ties into your lore. A subtle texture mimicking game terrain. Players geek out. And it doesn’t cost the earth if you plan.

Case Studies: Games That Got the Packaging Right (and Wrong)

Stories from the field beat theory every time. Let’s look at a few no-name examples from tabletop folks. They’ve scrapped with cost vs. durability. And came out with tales.

The good one first. A solo RPG builder picked 400gsm rigid boxes for a 2,000-unit Kickstarter. Price? $0.90 each. With custom slots for journals and dice. Outcome: Not a single shipping whine. Backers raved on the “weight” in feedback. Sales jumped 20% from buzz alone. They aced how to choose the right custom paper box. By sample-testing. Mailed to pals in different states. No harm? Green light.

Now the flop. A fresh card game team went dirt-cheap on 250gsm to nail $0.40. Looked slick online. But after drop? 15% came back dented. They shelled $800 on patches. And pushed reprints. Point? Strength checks aren’t extra. They’re your wallet’s pal. If prototyping, snag a few and rough ’em up. Sit. Drop. Ship far. Harsh. But it spots the frail ones.

These aren’t rare birds. Polls at game fairs say 70% of folks size up quality by the box upfront. Put cash there. Your budget goes further later.

Let me add one more yarn. A co-op game outfit mixed it up. Basic box for core. Upgrade for deluxe. Saved a bundle. But the cheap one still held. Because they reinforced corners cheap. Smart hack. You can too.

Smart Budgeting: Stretching Dollars Without Sacrificing Strength

You’re geared up for a plan now, right? Here’s how to sync cost vs. durability with your game’s budget. Phased picks that grow with wins.

- Nail a Per-Unit Cap Early: Shoot for 5-10% of total costs on packaging. For a $20 game, $1-2 tops. Track versus sales guesses. Simple spreadsheets do the trick.

- Buy Extra Smart: Grab 20% more than first run. Extra boxes? For add-ons later. Trims costs 10-15%. And covers redo risks.

- Green Twist for Gains: Eco papers (FSC-stamped) tack on $0.05. But draw in tree-hugger players. Hey, grants or crowd perks for green packs? That’s bonus dough.

And a odd bit. One shop guy I know pushes “box stretches”—pushing test ones to break in design. Sounds goofy. But it nabbed a stick fail that might’ve sunk a debut. Folks do funny stuff, huh?

To stretch further, think shipping hacks. Flat-pack options cut postage. Or bundle with game wraps. I’ve seen devs shave 8% off total by that. Small wins add up.

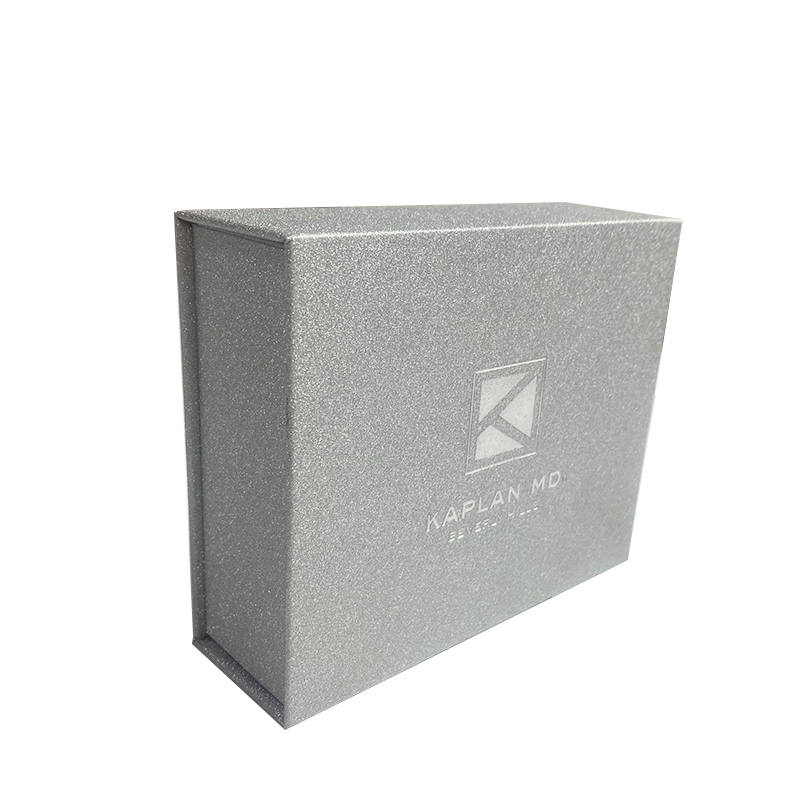

Meet Suba: Crafting Custom Paper Boxes That Fit Your Vision

When it’s time to pull the trigger, you need a partner who gets the grind. Enter Suba, a Shenzhen-based powerhouse with over 30 years in the custom paper box game. They’re all about turning your sketches into sturdy, standout packaging—whether it’s drawer-style sliders for easy component grabs or boutique-level finishes for that wow factor. Suba’s setup shines for game devs: flexible MOQs starting at 500 units, quick-turn prototypes in under two weeks, and a knack for blending affordability with rock-solid builds. From eco-friendly cardboards to embossed details, they handle the details so you can focus on gameplay. It’s the kind of reliability that turns one-off orders into long-haul collabs, keeping your budget in check while your games hit shelves intact.

What sets Suba apart is that hands-on touch. They send video updates on your run. Answer odd-hour emails. It’s like having a buddy in the factory. Not every supplier does that. Makes the process less scary for first-timers.

Wrapping It Up: Your Path to Packaging Peace

So, there you have it. The roadmap to mastering cost vs. durability. And nailing how to choose the right custom paper box for your game’s budget. It’s less about perfection. More about wise swaps. Beef up key spots. Test hard. And tap folks who know tricks. Your game deserves packaging that matches its fire. Not some throwaway that fizzles quick. Jump in. Mock up a few. And see how a firm box lifts it all. What’s your next step? Drop a line below. I’m all ears.

One last nudge. Packaging’s just the start. But get it right, and it snowballs. Fans share pics. Reviews glow. Your budget thanks you down the line.

Frequently Asked Questions

How do I balance cost vs. durability when starting with a tight game’s budget?

Start by pinning down your must-haves—like protecting cards from bends—then layer in materials like 350gsm paperboard for under $1 per unit. Test small runs to avoid big regrets, and remember, a durable box cuts long-term headaches more than it spikes upfront costs.

What’s the best way to figure out how to choose the right custom paper box for game components?

Map your contents first: Heavy minis need rigid stock; slim decks do fine with lighter weaves. Factor in shipping routes—international? Go corrugated. Chat with suppliers for samples; it’ll save you from guessing.

Can custom paper boxes be both affordable and tough enough for retail display?

Absolutely—think matte-laminated rigid board at $0.80 a pop. It stands up to shelf jostling and looks pro without the premium price. Just skip over-the-top finishes unless your budget’s got wiggle room.

How much does customization affect the cost vs. durability equation in paper boxes?

It nudges costs up 10-20%, but smart picks like spot UV boost grip without weakening structure. For games, prioritize closures over flashy cuts—they keep durability high while keeping things wallet-friendly.

Are there quick tips for testing durability on a shoestring game’s budget?

Grab cheap prototypes and go rogue: Drop ’em, stack ’em, even microwave one (kidding—sort of). Real talk, a $50 shipping sim to buddies across states reveals cracks faster than any lab.